What is a progressive cavity pump performance curve?

Progressive cavity pumps are widely used in various industries for the transport of fluids. Understanding their performance curves is crucial for selecting the right pump for specific applications. This article delves into the characteristics of progressive cavity pump performance curves, their significance, and the factors influencing them.

Understanding the Performance Curve

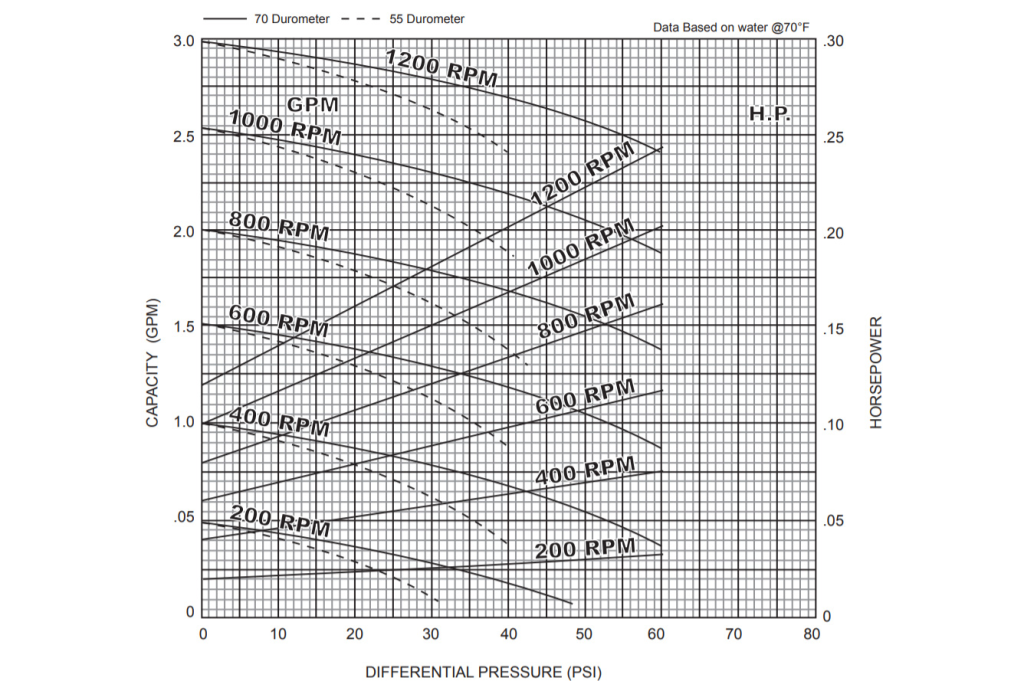

A performance curve for a progressive cavity pump is a graphical representation that illustrates the relationship between flow rate and pressure for the pump. It helps users understand how the pump will perform under different operating conditions. The curve typically displays several key parameters, including:

- Flow Rate: The volume of fluid the pump can move over a specific time period.

- Differential Pressure: The pressure increase that the pump can generate to move the fluid through the system.

- Viscosity: The thickness of the fluid being pumped, which affects flow dynamics.

Key Features of the Performance Curve

- Flow Rate vs. Pressure: The curve highlights how flow rate decreases as pressure increases. This inverse relationship is fundamental in understanding pump efficiency and operational limits.

- Efficiency Points: The curve will indicate optimal efficiency points, allowing users to identify the best operating conditions for maximum performance.

- NPSH Requirement: Net Positive Suction Head (NPSH) is critical for preventing cavitation. The performance curve often includes a section that indicates the NPSH required for various flow rates.

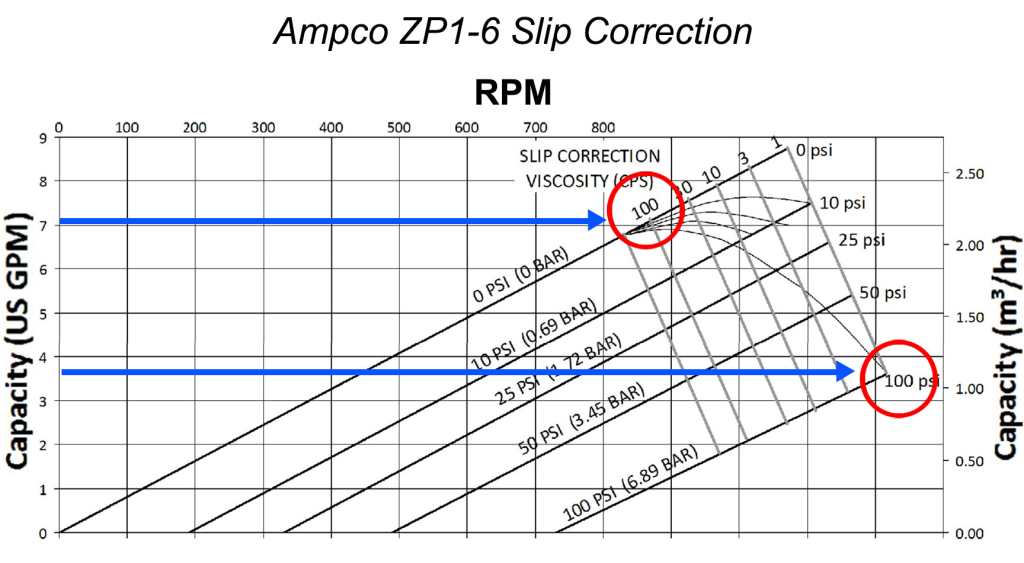

- Viscosity Influence: Different fluids have varying viscosities, which can alter the performance curve. The curve may shift as the viscosity of the fluid changes, impacting flow rate and pressure.

Importance of the Performance Curve

The performance curve serves multiple purposes:

- Pump Selection: By analyzing the curve, engineers can select a pump that meets the specific requirements of their application, ensuring efficiency and reliability.

- System Design: Understanding how the pump interacts with the entire system helps in designing pipelines and fittings that accommodate the pump’s characteristics.

- Operational Monitoring: Regularly reviewing the performance curve can help operators identify changes in pump behavior, signaling potential maintenance needs.

- Troubleshooting: If a pump is not performing as expected, comparing its actual performance against the curve can help identify issues such as wear, blockage, or changes in the fluid being pumped.

Factors Affecting Performance

Several factors can influence the performance curve of a progressive cavity pump:

- Fluid Characteristics: The type of fluid, including its viscosity, density, and presence of solids, plays a significant role in pump performance.

- Temperature: Variations in temperature can alter the viscosity of the fluid, affecting the flow rate and pressure.

- Wear and Tear: Over time, components of the pump may degrade, leading to changes in the performance curve.

- Operating Conditions: Changes in suction conditions, such as pressure drops or changes in elevation, can impact the pump’s efficiency.

Conclusion

In summary, the progressive cavity pump performance curve is an essential tool for understanding how these pumps operate under various conditions. By analyzing the curve, users can make informed decisions regarding pump selection, system design, and maintenance, ultimately leading to improved efficiency and reliability in fluid transport applications. Understanding the nuances of the performance curve is crucial for anyone involved in the operation or design of systems utilizing progressive cavity pumps.