Understanding the Components in Seepex Pump Drawings

Seepex pumps are renowned for their reliability and efficiency in handling various fluids. To fully grasp their functionality, one must delve into the components illustrated in Seepex pump drawings. This article aims to clarify these components and their significance in the overall design.

Overview of Seepex Pumps

Seepex is a prominent manufacturer of progressive cavity pumps, often utilized in industries such as wastewater treatment, food processing, and chemical manufacturing. The design of these pumps allows for the gentle handling of viscous fluids, making them ideal for a wide range of applications. Understanding the components in the pump drawings is crucial for maintenance, troubleshooting, and optimization.

Key Components in Seepex Pump Drawings

When examining Seepex pump drawings, several key components stand out. Each part plays a vital role in the pump’s operation. Below is a list of these components along with their functions:

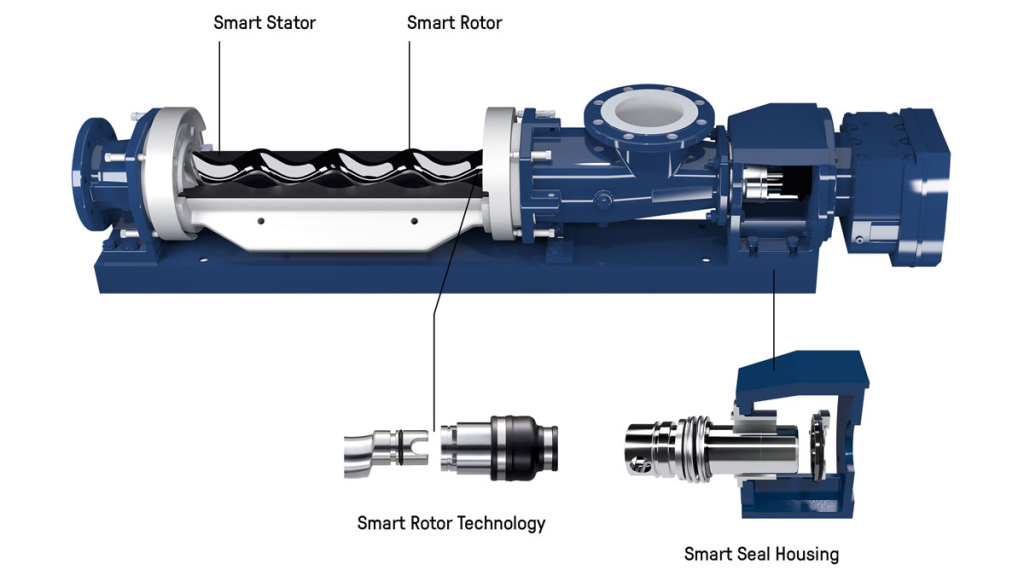

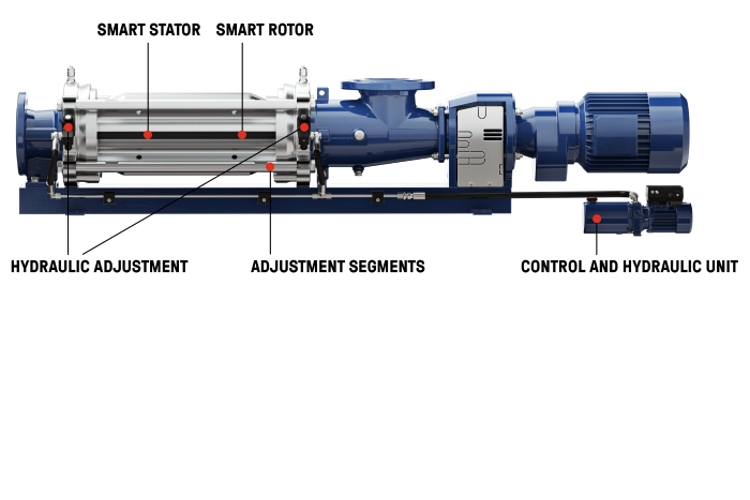

- Stator: The stator is a stationary part that houses the rotor. It is typically made of elastomer or other durable materials, designed to create a tight seal with the rotor, facilitating the movement of fluids.

- Rotor: The rotor is the heart of the pump, rotating within the stator to create a cavity. As it turns, it moves the fluid through the pump, ensuring a steady flow.

- Pump Housing: This component encloses the stator and rotor, providing structural integrity. It is designed to withstand pressure and protect the internal components from external damage.

- Drive Shaft: The drive shaft connects the rotor to the motor, transmitting the rotational force necessary for the pump’s operation.

- Suction and Discharge Ports: These ports allow fluid to enter and exit the pump. Their design is critical for minimizing turbulence and ensuring efficient fluid transfer.

- Bearing Assemblies: Bearings support the rotor and drive shaft, reducing friction and wear during operation. Proper lubrication of these components is essential for longevity.

- Seals and Gaskets: Seals prevent leaks between the pump housing and the rotating components. Gaskets ensure a tight fit between flanges and connections, maintaining the pump’s efficiency.

Importance of Understanding Pump Drawings

Familiarity with Seepex pump drawings provides several advantages:

- Maintenance: Knowing the components aids in identifying wear and tear, allowing for timely maintenance and replacement.

- Troubleshooting: Understanding how each part functions can help diagnose issues quickly, minimizing downtime.

- Optimization: Awareness of component interactions enables operators to adjust settings for improved performance and efficiency.

- Training: Educating staff on pump components fosters a safer workplace and enhances operational knowledge.

Conclusion

In summary, understanding the components in Seepex pump drawings is essential for anyone involved in the operation or maintenance of these pumps. Each component plays a crucial role in ensuring the pump functions efficiently and reliably. By gaining a clearer insight into these drawings, operators can enhance their maintenance practices, troubleshoot effectively, and optimize pump performance, ultimately leading to greater operational success.